It was well known that the car market was very crowded now, but most of them were designed and configured on the surface of the roll, and the Starway Lunar Roll was rolled in places that many people couldn’t see. Not long ago, someone transported a Starway Lunar Roll down the hillside to a professional design shooting range and used various firearms to shoot to verify the sturdiness of the car. As a result, even the most powerful gun couldn’t penetrate it. It could be said that while others were still rolling the configuration, the Starway Lunar Roll had already begun to roll safely.

Safety is the most valuable aspect of a car

It is worth mentioning that this "target" is the first peak rolling challenge of the China Automotive Center in China

At that time, the new generation of Lanyue rolled 8 laps from the steep slope of 45 ° on the 25-meter-high peak of the mountain to the ground. This was also the first time in China that the difficulty of rolling was based on real-life scenarios.

After experiencing a terrifying tumble, the body structure of Xingtu Lanyue remained generally intact, the restraint system responded in time, and the doors could be opened normally. And in the score of Zhongqi, the car has achieved excellent evaluation results in terms of structural performance, restraint performance, and functional performance.

The existence of routine car safety tests allowed cars to have a basic line of safety. Most manufacturers only needed to reach the passing line, but in the face of safety accidents like this cliff rolling limit, it was natural that absolute safety could not be guaranteed. As a high-end brand and the background of a traditional large factory, Xingtu was naturally involved in safety.

"Catching bullets with your bare hands", it turns out that rolling over the cliff is not the safety limit of the moon

If the cliff roll test considered the safety of the overall structure, then the hard-loaded bullet Star Road Lunar Ranging was a bit outrageous, because the requirements for the body materials were quite high. After all, the well-known bulletproof cars were modified with special materials.

The most unbelievable thing was that the car that underwent the shooting test was the rolling test vehicle. This was like asking a seriously injured person to take a professional boxer’s punch. The difficulty of the challenge could be imagined.

Throughout the test, we saw a variety of firearms that only appear in video games, including revolvers, pistols, AK47 rifles, double-barreled shotguns, etc. For visual comparison, we also brought pans, engineering steel, and the B-pillar of a Japanese car to be shot with these firearms.

The test results once again proved the superiority of Xingtu Lanyue in key components. Because neither the pan nor the B-pillar of the Japanese car can escape the fate of being penetrated, especially the B-pillar of the Japanese car, which can only withstand the smallest caliber revolver, while Xingtu Lanyue, whether it is a pistol or an AK47 rifle, cannot penetrate it, and the bullet marks on the surface are also very shallow, even the most powerful double-barreled shotgun can only penetrate a layer of skin on the surface.

Harder than a nuclear submarine, the materials used for the star’s journey to the moon are not ordinary

After these extreme tests, I believe many people are as curious as I am about what material this car is made of. Take the B-pillar as an example. Not only is the steel made of thermoformed steel, but also the hot stamping technology (UHHSP) is used to make the tensile strength exceed 1500 MPa, which is harder than that of ordinary nuclear submarines. Moreover, the entire B-pillar is composed of three layers, which greatly enhances the structural strength of the B-pillar.

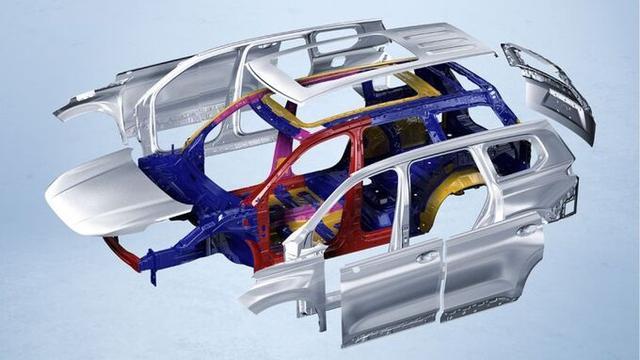

In addition to the super-strong B-pillar, the body-in-white is also designed with a cage-type energy-absorbing space capsule. According to various collision conditions, three load transfer paths are designed at the front of the vehicle, and high-strength support structures are used at key stress-bearing parts. The internal structure is more robust and stable.

In addition, from parts to skeleton, this car adopts international advanced tooling matching technology and stability control system manufacturing, pursues 1mm body quality, and meets Euro NCAP, IIHS, and FMVSS international top safety standards. Moreover, Xingtu Lanyue was born in the earliest, largest and most fully functional collision safety laboratory branding in China. During the research and development process, it went through 1 million hours + calculation simulation, more than 1,000 simulations, and 62 vehicle crash tests, and won the TOP Safety dual-car crash test with nearly full marks, and obtained the C-NCAP five-star collision safety certification.

Write at the end:

It was originally a good thing for the car to be rolled in, because it could speed up the process of survival of the fittest, but if it was only made on the surface, it was doomed to not last long, because once the "secret" was exposed and there was a crisis of trust, it would be difficult to recover. We consumers should also be more careful when choosing products, not to be confused by appearances, but to look at the inner quality. Cars like Xingtu Lanyue that pay attention to the inside are more worthy of our attention.

关于作者